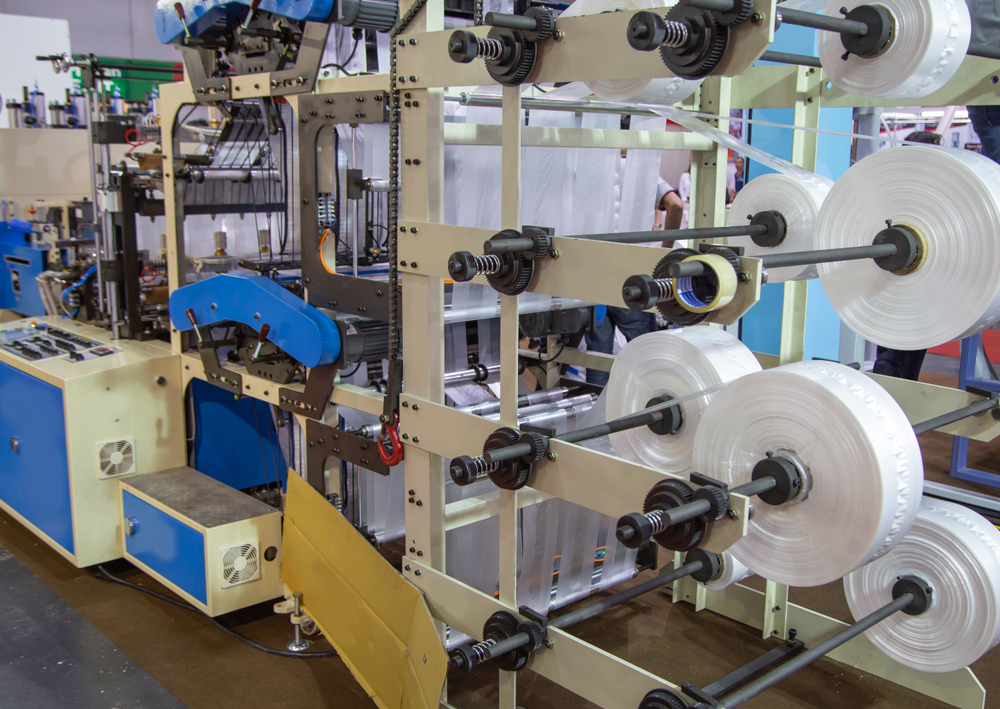

Extrusion operators are specialized technicians who work with extrusion machines, a key component in manufacturing processes across various industries, including plastics, metals, and food production. These operators are tasked with the setup, operation, and maintenance of machinery that forces materials through a die to create products with a specific cross-sectional shape.

The extrusion industry plays a vital role in modern manufacturing, producing a wide array of products from plastic pipes to metal components. At the heart of this industry are extrusion operators—skilled technicians responsible for setting up, maintaining, and operating the machines that shape raw materials into usable forms.

Key Responsibilities

- Machine Setup and Operation: Operators are responsible for configuring the extrusion machines according to production requirements. This involves calibrating the machine settings, loading raw materials, and monitoring the process to ensure it runs smoothly.

- Maintenance and Troubleshooting: Routine maintenance is critical to prevent machine downtime. Operators are expected to perform regular checks, clean equipment, and carry out minor repairs. For more complex issues, they work alongside maintenance teams to resolve problems.

- Quality Control: Ensuring the quality of the output is a crucial part of the operator’s role. They must inspect products to verify that they meet the specified standards and make necessary adjustments if there are deviations.

- Safety and Compliance: Given the potential hazards associated with heavy machinery, adhering to safety protocols is essential. Operators must follow all safety guidelines to protect themselves and their colleagues from accidents.

Skills and Qualifications Needed

A successful extrusion operator requires a blend of technical skills, mechanical aptitude, and attention to detail. While some companies may hire individuals with a high school diploma and provide on-the-job training, many prefer candidates with a technical diploma in industrial technology or mechanical engineering.

Essential Skills

- Mechanical Aptitude: A strong understanding of machinery and its components is fundamental. Operators must be able to troubleshoot and solve mechanical issues quickly.

- Attention to Detail: Precision is key in ensuring that products meet exact specifications. Operators must consistently monitor the extrusion process and make fine adjustments as needed.

- Problem-Solving: The ability to identify and address issues promptly is critical for maintaining production efficiency.

- Communication: Operators often work in teams, so clear communication is necessary to ensure that production runs smoothly and issues are addressed collectively.

Career Path and Professional Development

Starting as an entry-level extrusion operator offers a gateway into a stable and potentially lucrative career. With experience and continued education, operators can advance to supervisory roles, quality control positions, or even specialized technical roles.

Training and Certifications

- On-the-Job Training: Most operators begin their careers with on-the-job training, which typically lasts from a few months to a year. This training covers machine operation, safety protocols, and basic troubleshooting.

- Certifications: Earning certifications such as the Certified Extrusion Operator (CEO) can enhance an operator’s career prospects. These certifications often cover advanced topics like equipment maintenance, safety standards, and process optimization.

- Continuing Education: To stay competitive, operators are encouraged to pursue further education, such as courses in mechanical engineering, industrial technology, or business management. These qualifications can open doors to higher-level positions within the industry.

Salary Overview for Extrusion Machine Operators in 2024

As of 2024, the average salary for an extrusion machine operator in the United States varies depending on experience, location, and the specific industry. Typically, extrusion operators earn an average annual salary ranging from $35,804 to $55,374. The median salary is around $44,831 per year, with the hourly wage typically falling between $17.21 to $22. Experienced operators in high-demand regions or specialized sectors may see wages at the higher end of this spectrum, or even beyond.

Salaries can also be influenced by additional factors such as certifications, the complexity of machinery handled, and the specific materials processed (e.g., plastics vs. metals). Extrusion operators in certain regions or industries may also receive bonuses or additional compensation based on production goals and company performance.

These figures provide a snapshot of what you can expect in this role, but individual earnings will vary based on personal qualifications and the job market in your area.

The Extrusion Industry: An Overview

The extrusion industry is a cornerstone of manufacturing, with applications spanning from creating everyday consumer products to specialized components used in aerospace and automotive industries. The versatility of the extrusion process allows it to be used with various materials, including plastics, metals, and even food products.

Key Sectors

- Plastics Industry: One of the largest sectors utilizing extrusion processes, the plastics industry produces items like pipes, sheets, and films. The precision and efficiency of extrusion make it a preferred method for manufacturing these products.

- Metals Processing: Extrusion is also crucial in metalworking, where it is used to form components for construction, automotive, and aerospace applications. This process is particularly important for shaping materials like aluminum and copper.

- Food Production: In the food industry, extrusion is employed to produce items such as pasta, cereals, and snacks. The process ensures consistent shapes and textures, essential for consumer products.

Hiring Extrusion Operators: What Employers Need to Know

For employers looking to hire skilled extrusion operators, it is crucial to understand the specific qualifications and traits that make a candidate suitable for this role. Beyond technical skills, employers should look for candidates with a strong commitment to safety, an eye for detail, and the ability to work effectively within a team.

Recruitment Tips

- Prioritize Experience: While education is important, hands-on experience often proves to be the most valuable asset. Candidates with previous experience in similar roles are likely to require less training and adapt more quickly to the job.

- Assess Problem-Solving Abilities: During the recruitment process, consider asking candidates to describe how they have handled complex problems in the past. This can give insight into their ability to troubleshoot and maintain production efficiency.

- Emphasize Safety Culture: Given the potential hazards in an extrusion environment, it is vital to hire individuals who prioritize safety. Look for candidates who have a strong track record of adhering to safety protocols and contributing to a safe work environment.

Key Functions and Duties

- Precision Setup and Calibration: Expertly configure extrusion equipment, ensuring that machine settings are tailored to meet exact production specifications and quality standards.

- Operational Excellence: Take command of the extrusion process, continuously monitoring and adjusting to maintain product consistency and optimal throughput.

- Quality Assurance Monitoring: Perform rigorous inspections of output, making necessary real-time adjustments to uphold the highest quality standards.

- Proactive Troubleshooting and Issue Resolution: Swiftly address and resolve any operational issues that arise, minimizing disruptions and ensuring seamless production flow.

- Preventative Maintenance: Execute regular maintenance routines, including cleaning, lubrication, and part replacements, to maximize equipment reliability and longevity.

- Collaborative Workflow Management: Coordinate closely with team members to ensure a steady supply of materials, enabling continuous operation of the extrusion lines.

- Accurate Documentation and Reporting: Maintain meticulous records of machine settings, production metrics, and maintenance activities to support continuous improvement initiatives.

- Safety and Compliance Leadership: Champion safety protocols, rigorously adhering to guidelines to maintain a safe, compliant, and efficient work environment.

- Mentorship and Knowledge Transfer: Guide and train new team members, sharing expertise in machine operation and safety practices to foster a well-prepared and cohesive team.

Qualifications and Experience

- Educational Credentials: A foundational education, such as a high school diploma or equivalent, is required, with a strong preference for candidates who have pursued advanced technical training or hold relevant certifications.

- Industry Experience: Proven experience in extrusion or a related manufacturing role, with demonstrated mechanical aptitude and a deep understanding of complex machinery.

- Technical Expertise: Thorough knowledge of extrusion processes and equipment, coupled with the ability to interpret technical documents and apply this knowledge effectively.

- Safety Commitment: A strong commitment to safety, demonstrated through a deep understanding of industry protocols and a track record of maintaining a safe work environment.

- Detail-Oriented Mindset: A meticulous approach to work, ensuring all products meet or exceed quality standards.

- Problem-Solving Skills: Sharp analytical skills and a resourceful mindset, capable of quickly resolving operational challenges.

- Team Collaboration: Strong communication and teamwork skills, essential for working effectively with colleagues and supervisors to achieve production goals.

- Physical Stamina: The physical ability to handle the demands of the role, including standing for long periods and managing heavy materials, is crucial.

Strategies for Becoming a Successful Extrusion Operator

If you’re considering a career as an extrusion operator, here are some key strategies to help you succeed:

If you’re considering a career as an extrusion operator, here are some key strategies to help you succeed:

- Exercise Patience: Mastering the role of an extrusion operator can take time, often requiring up to a year of hands-on training with a seasoned operator. Set clear goals and track your progress to stay motivated during this learning period.

- Enhance Your Skill Set: Focus on developing essential skills such as effective communication, tool proficiency, and a strong understanding of safety protocols. These are critical for your success in the role.

- Understand Job Requirements: Different employers may have varying qualifications for extrusion operators. Research these requirements in advance, including any specific certifications or degrees needed, to ensure you’re well-prepared for the role.

By following these strategies, you can build a solid foundation for a rewarding career as an extrusion operator.

Comparable Roles to an Extrusion Operator

If you’re exploring careers similar to that of an extrusion operator, consider these roles:

- Forklift Operator: Operates forklifts to transport heavy materials in warehouses or construction sites. This role typically requires basic training and focuses on material handling.

- Assembly Inspector: Ensures products meet quality standards by identifying defects, taking measurements, and maintaining detailed records.

- Maintenance Technician: Responsible for repairing and maintaining machinery and facilities, often requiring a broad skill set and technical knowledge.

- Operations Supervisor: Manages the daily activities of a production unit, focusing on process efficiency and team management.

- Production Technician: Assists in assembling and testing products, often working closely with quality assurance to ensure standards are met.

- Manufacturing Engineer: Designs and optimizes manufacturing processes and equipment, often requiring advanced technical knowledge and problem-solving skills.

- Safety Specialist: Oversees workplace safety programs, ensuring compliance with regulations and protecting employees in manufacturing environments.

Plastic vs. Metal and Food Extrusion Operators: A Comparative Analysis

Plastic extrusion operators and other types of extrusion operators, such as those working with metals or food products, share many core responsibilities, including setting up machines, monitoring production, and ensuring quality. However, plastic extrusion operators typically work with polymers, which require a deep understanding of plastic materials’ properties, such as melt flow and cooling rates. In contrast, metal extrusion operators deal with higher temperatures and pressure, requiring knowledge of metallurgy. Food extrusion operators focus on consistency and safety, emphasizing hygiene and food-grade standards. Each specialization requires unique expertise tailored to the material being processed.

Industry Trends and Innovations

The extrusion industry continues to evolve with advancements in technology and shifts in market demand. Notably, the integration of automation and a focus on sustainability are reshaping how extrusion processes are carried out.

Automation

The adoption of automation in extrusion processes has significantly increased productivity and consistency. Automated systems can handle repetitive tasks, allowing operators to focus on more complex aspects of production. Familiarity with automation technologies is becoming increasingly important for operators, as these systems become more prevalent in manufacturing plants.

Sustainability

With growing concerns about environmental impact, the extrusion industry is moving towards more sustainable practices. Techniques such as lean manufacturing and Six Sigma are being applied to optimize material usage and reduce waste. Operators are now expected to play a role in these sustainability efforts by adhering to practices that minimize the environmental footprint of production processes.