Regional Supplemental ServicesOn-Demand Reliable Workforce

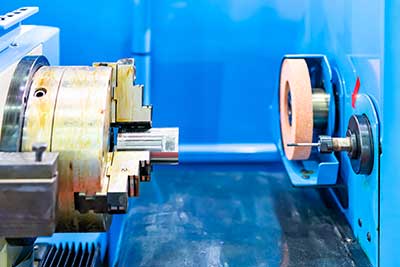

ID Grinder Staffing

When your operation requires temporary ID Grinder Operators to handle fluctuating demand or to tackle time-critical projects, RSS stands ready to support you. Our adaptable staffing solutions are crafted to fulfill your requirements, ensuring uninterrupted workflow.

Rapid Staffing Services: We deliver prompt staffing responses to urgent needs while upholding strict safety protocols.

Customized Staffing Strategies: At RSS, we collaborate closely with you to create a staffing strategy that not only meets your operational objectives but also fits within your financial plans.

Reliable ID Grinder Operators with Experience

Positions We Fill

ID Grinder Operator

CNC ID Grinder Operator

Precision Grinder Operator

Tool Grinder (ID Grinding)

Journeyman Grinder

Cylindrical Grinder Operator (ID)

And More!

Why RSS?

Specialized Recruitment: RSS has a rigorous process for screening and recruiting candidates with specialized skills in ID grinding. This means you’re getting access to a pool of experienced candidates adept at handling the intricacies of ID grinding operations.

Flexibility: RSS provides temporary staffing solutions that offer flexibility in managing your workforce according to project demands and workload fluctuations. This can help you maintain productivity without the long-term commitment of direct hires.

Efficiency: By leveraging our expertise in staffing, RSS can quickly fill vacancies, reducing downtime and helping maintain or enhance operational efficiency. Our market knowledge and network of skilled professionals means we can find the right fit for your specific needs on time.

Cost-Effective: A temporary staffing service can be more cost-effective than in-house recruitment. It saves on advertising, screening, and interview costs, as well as the time and resources that would otherwise be spent on these processes.

Industry Expertise: We deeply understand the manufacturing and production industry’s needs. Our expertise allows us to better match candidates with job opportunities that fit both the candidate’s skills and the employer’s requirements.

Reach Out Today

Contact RSS to learn how our tailored temporary staffing solutions can help keep your operations running smoothly, efficiently, and safely.

Client Testimonials

Frequently Asked Questions

What industries do ID Grinder Operators work in?

ID (Inside Diameter) grinders are utilized across a broad spectrum of industries where precision internal dimensions and smooth finishes are critical. Here are some of the key industries where ID grinders play a vital role:

- Aerospace: For precision grinding of internal engine components, hydraulic system parts, and other aerospace components that require tight tolerances and smooth internal surfaces.

- Automotive: In manufacturing components such as gears, engine cylinders, and bearings that demand precise internal dimensions for optimal performance and reliability.

- Medical Device Manufacturing: For creating precise internal features on surgical instruments, implants, and equipment where exact dimensions and finishes are critical for patient safety and device effectiveness.

- Tool and Die Making: In crafting molds, dies, and other precision tools that require accurately ground internal surfaces to produce parts within specific tolerances.

- Bearing Industry: To grind the internal surfaces of ball and roller bearing races, ensuring they meet the precise specifications for smooth operation.

- Electrical and Electronics: In producing components for electric motors, generators, and various electronic devices requiring precise internal grinding for optimal performance.

- Metalworking and Fabrication: For custom machining and fabrication of industrial components, such as pipes, fittings, and specialty tools, that require precise internal dimensions.

- Defense and Military: In the manufacturing of components for military equipment and weapons systems, where precise internal dimensions are crucial for functionality and reliability.

- Industrial Machinery: For parts in machinery and equipment used across various sectors, including manufacturing, energy, and agriculture, where internal dimensions and finishes are critical for operational efficiency.

- Energy Sector: Particularly in oil and gas, nuclear, and renewable energy, for grinding internal surfaces of components used in turbines, pumps, and other critical equipment.

What does and ID Grinder Operator do?

An ID (Inside Diameter) Grinder Operator specializes in operating machinery designed to grind the inside diameter of cylindrical objects to ensure they meet precise specifications. The role involves several key responsibilities:

- Setting Up Machinery: Preparing the ID grinding machine for operation, which includes selecting and installing the appropriate grinding wheels and fixtures, adjusting machine settings, and calibrating equipment for precise internal grinding.

- Reading Blueprints: Understanding and interpreting technical drawings and blueprints to grasp the specific dimensions, tolerances, and surface finishes required for the interior surfaces of the workpieces.

- Material Preparation: Positioning and securing the workpieces onto the machine or within the fixture, ensuring that they are properly aligned and ready for grinding.

- Operating the Machine: Skillfully controlling the ID grinding machine to remove material from the inside surface of the workpiece, achieving the desired diameter, roundness, and surface finish.

- Quality Control: Performing measurements and inspections of the ground internal diameters using micrometers, calipers, and other precision measuring instruments to ensure they meet the specified tolerances and quality standards.

- Troubleshooting: Identifying and resolving issues with the grinding process, such as adjustments to machine settings or changing grinding wheels, to maintain high-quality output and minimize defects.

- Maintenance: Performing routine maintenance on the ID grinding machinery to ensure it operates efficiently and safely, including cleaning, lubricating, and making minor repairs.

What is the difference between an OD grinder and an ID grinder?

OD (Outside Diameter) grinders and ID (Inside Diameter) grinders are cylindrical grinding machines, each designed to handle different aspects of machining round or cylindrical parts. The key difference between these two types of grinders lies in where the grinding operation is performed on the workpiece:

OD (Outside Diameter) Grinder:

- Function: OD grinders are used to shape the external surface of a workpiece. This includes grinding the outer surface of cylindrical parts to achieve the desired diameter, roundness, finish, or other specifications.

- Working Principle: The workpiece is mounted between centers (i.e., fixed points at both ends) or on a chuck, and it rotates around its axis. The grinding wheel, which also rotates, is brought into contact with the outside diameter of the workpiece, removing material to shape the outer surface.

- Applications: OD grinding is commonly used to finish shafts, rods, rollers, and other cylindrical components.

ID (Inside Diameter) Grinder:

- Function: ID grinders are used to grind the inside surface of a hollow part or bore. The objective can be to achieve a precise internal diameter, finish, or to remove material from the inside of a workpiece.

- Working Principle: The workpiece is held in place while the grinding wheel, which is mounted on a spindle, is inserted into the workpiece to grind its internal surfaces. The grinding wheel rotates, and its position is carefully controlled to achieve the desired diameter and surface finish inside the bore.

- Applications: ID grinding is often used for finishing the internal diameters of bearings, bushings, tubes, and other cylindrical components with internal features.

Comparison:

- Location of Grinding Area: The most significant difference is where the grinding is performed relative to the workpiece—OD grinders work on the external surfaces, while ID grinders focus on the internal surfaces.

- Tooling and Setup: ID grinding setups and tooling are generally more complex due to the need to accommodate internal grinding within hollow parts or bores. OD grinding setups are typically more straightforward, as they involve grinding the outer surface of solid cylindrical parts.

- Applications: Each type of grinder is chosen based on the specific requirements of the project, depending on whether internal or external dimensions need to be precision-machined.

In essence, the choice between an OD grinder and an ID grinder will depend on the specific grinding requirements of the workpiece, including whether the focus is on internal or external dimensions.

For Employers Looking for Staffing Solutions?

Employers please submit the form below regarding your need for staffing solutions.